Description

Yuantuo’s Long Rod Quench & Temper Line leverages advanced induction heating technology for hardening, strength enhancement, and toughness control across a wide range of steels. The system processes steel bars, threaded rods/lead screws, sucker rods, and other elongated workpieces, meeting high-throughput, high-precision heat-treatment requirements.

Key Features

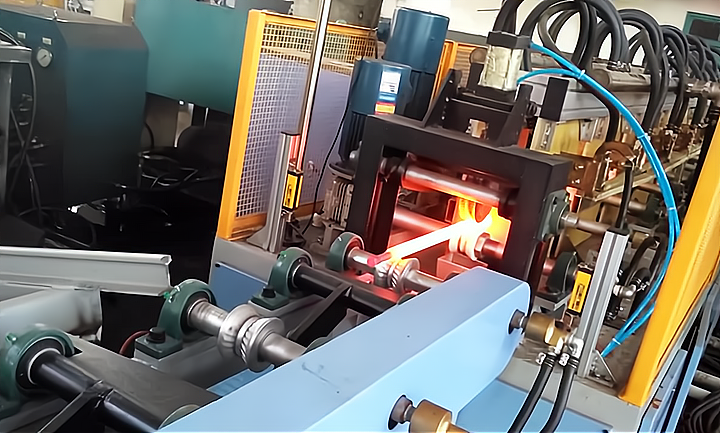

- High-Efficiency Induction Heating:Powered by medium-frequency (MF) induction, the line precisely controls the heating curve of bars and long rods. Surface-to-core temperature delta is maintained within ±10 °C to ensure excellent thermal uniformity and precise temperature control.

- Energy-Saving & Grid-Friendly:Low-harmonic, multi-band high-efficiency power modules with a high power factor minimize energy waste and reduce interference to the plant power network.

- Fully Automated Control:A PLC-based control system automates the entire cycle—heating, quenching, and tempering—while continuously monitoring and adjusting process parameters in real time to achieve consistent metallurgical results part after part.

- Modular Inductor Design:Modular inductors enable fast coil changeover, shorten maintenance windows, and maximize line availability and productivity.

Applications

Ideal for heat-treating and quench-tempering of diverse long products in machinery manufacturing, automotive components, construction/engineering equipment, and the oil & gas sector, especially:

- Steel Bars: Carbon steels, alloy steels, shaft-type components, etc.

- Threaded Rods / Lead Screws: Used in transmission systems and general machinery.

- Sucker Rods: Quench-tempering for oilfield service requirements.

Process Flow

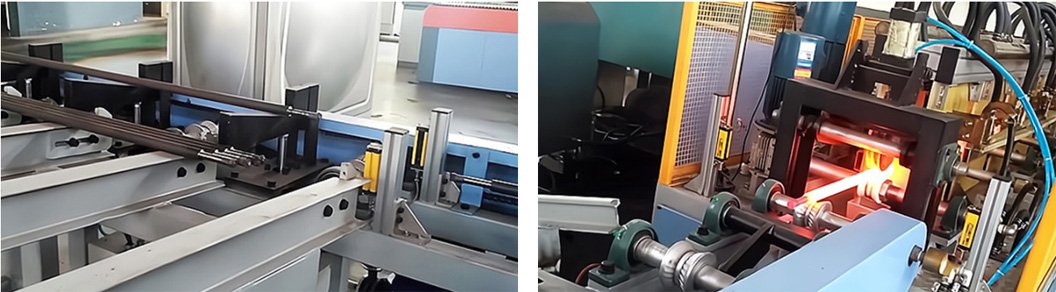

- Induction Heating:Long rods/bars are fed automatically into the inductor, where they are rapidly heated to the specified austenitizing (quenching) temperature.

- Spray Quenching:Heated parts enter the spray quench chamber for high-pressure water quenching, forming a hardened case while preserving core toughness.

- Tempering & Equalizing:Quenched parts pass through the tempering section. Controlled equalizing ensures uniform temperature to prevent brittleness from rapid cooling and to dial in the required combination of strength and toughness.

- Cooling & Discharge:After tempering, parts are further cooled and conveyed to the discharge/collection station, completing the automated heat-treatment cycle.

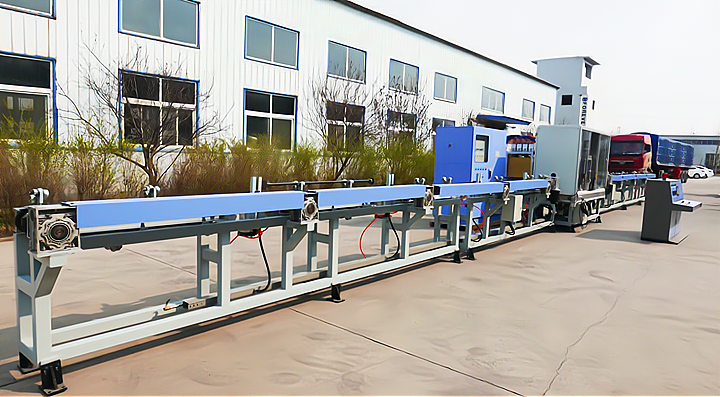

System Configuration

- Power Supply:High-efficiency IGBT power supplies with adjustable power and frequency precisely control the heating process. Each heating section is equipped with an independent power module for stable, flexible operation.

- Induction Heater:Inductors are engineered to match workpiece size and process specifications, ensuring fast, uniform, and efficient heating.

- Quench & Temper Tanks:Quench and temper cooling tanks are fabricated from 304 stainless steel and fitted with flowmeters and pressure gauges to maintain consistent cooling performance during quenching and tempering.

- PLC Automation:Siemens PLC with HMI touchscreen provides real-time data visualization and closed-loop control, automatically optimizing process parameters for accuracy and efficiency.

- Conveyance & Rollers:Non-magnetic stainless-steel rollers with VFD-driven motors and gear reducers ensure smooth transport and stable rotation/heating of the workpiece.

Yuantuo’s Long Rod Quench & Temper Line combines advanced induction heating with full automation to deliver stable, reliable, and energy-efficient quenching and tempering—helping manufacturers boost throughput, improve product quality, and reduce operating costs.