Description

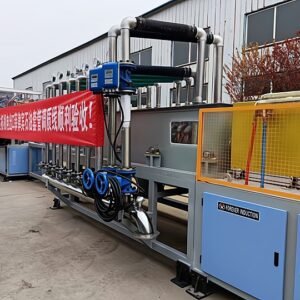

The Induction Heating System for Slab Temperature Equalizing, designed and manufactured by Hebei Yuantuo Electromechanical Equipment Co., Ltd., is purpose-built for “top-up” heating in steelmaking lines. Using advanced induction technology, it significantly improves heating efficiency and temperature accuracy at the equalizing stage, ensuring uniform slab temperature and stable downstream processing performance.

Power System

- Power Range: 1,000–12,000 kW

- Frequency: 500–1,200 Hz

- Flexible topology: Single power module operation or multi-module paralleling, configurable to production demand for high-capacity, high-efficiency heating.

Throughput

- Hourly output: 40–300 t/h, supporting large-scale production.

Applicable Slab Sizes

- Width: 200–1,500 mm

- Length: 3,000–12,000 mm

Covers a wide range of common slab specifications and process routes.

Line Advantages

- Independently Driven Feed System:Each axis is driven by its own motor–gear reducer. A multi-axis drive architecture under a single VFD keeps axes synchronized, delivering stable, precise feeding and consistent residence time.

- Guiding System:Non-magnetic 304 stainless-steel guide rollers provide compliant support to accommodate slab curvature, maintaining smooth transport and avoiding uneven heating due to bending.

- Closed-Loop Temperature Control:Infrared pyrometers integrated with a PLC form an automatic temperature-control loop. Based on incoming slab temperature and line speed, the system adjusts power in real time to hold a constant setpoint across the entire heating zone, minimizing temperature fluctuation and protecting product quality.

- Industrial PC (IPC) HMI & Smart Control:The IPC displays live operating parameters and system status, with recipe memory, data logging, and print/export functions. Built-in fault alarms and automatic power regulation enhance process stability and enable true constant-temperature operation.

Yuantuo Technical Advantages

1、Efficient Induction Heating:

Advanced coil design and MF power deliver rapid, uniform heating, improving throughput while reducing specific energy consumption.

2、Flexible Power Configuration:

Operate single supplies or parallel multiple modules to match plant capacity and redundancy requirements—maintaining efficiency and stability across a wide load range.

3、Accurate Temperature Control & Automation:

The closed-loop temperature system keeps each slab within tight tolerances throughout the process, supporting consistent metallurgical results and downstream rolling quality.

4、Application-Ready Engineering:

Designed with process adaptability in mind, the system handles various slab sizes and routes, providing reliable, high-stability equalizing solutions for diverse production setups.

5、Proven in Global Markets:

Yuantuo systems are deployed in Russia and other international markets, earning trust for dependable performance in demanding steel production environments.

Choose Yuantuo’s induction solution to achieve efficient, stable slab temperature equalizing.

Contact us for detailed quotations and customized engineering support.