Description

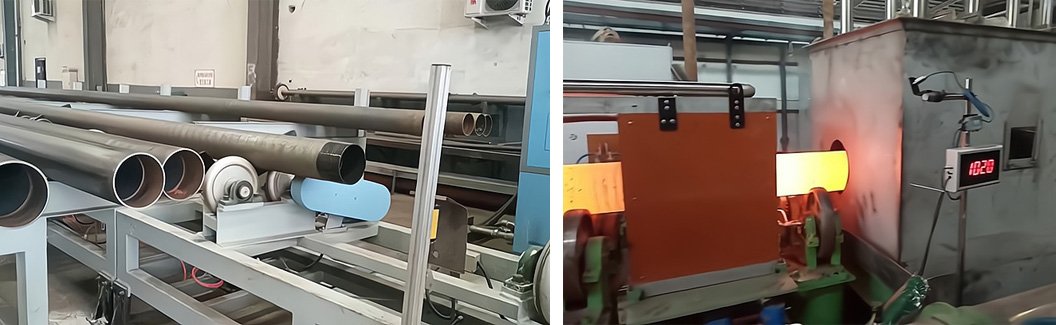

Yuantuo’s induction heat-treatment line for large-diameter seamless pipes is engineered for inner/outer surface quenching and full quench-and-temper processes on large pipes and OCTG (casing/tubing). The system balances surface hardness with core toughness to meet demanding mechanical-property requirements—providing a reliable solution for high-quality steel pipe production.

Power & Throughput

- Quenching Power: 750–3,500 kW @ 0.5–4 kHz

- Tempering Power: 400–1,600 kW @ 0.5–2.5 kHz

- Hourly Output: 2–10 t/h (configurable to order volume and line speed)

- Applicable Diameters: Ø200–1,000 mm

Multiple power configurations are available to match small-batch trials through to high-capacity production.

Line Advantages

Rotary Counter-Roller Conveyance

A self-rotation, counter-roller design keeps the pipe rotating during heating, minimizing bending/ovality and improving circumferential temperature uniformity and dimensional accuracy.

Individually Driven VFD Axes

Each roller axis uses its own motor–gear reducer with an independent VFD. Segment-wise speed control adapts residence time to different grades, diameters, and wall thicknesses, improving process flexibility and repeatability.

Robust Recipe Management

A recipe system recalls process parameters automatically based on input such as grade, OD, and wall thickness. This shortens changeovers, reduces manual error, and sustains consistent metallurgical results.

Multi-Loop Closed-Loop Control

For regions with unstable utilities, the system employs high-grade temperature/voltage feedback loops. It maintains steady operation and target setpoints even with ±20% mains fluctuation, helping ensure uniform properties.

High Stability & Reliability

Mechanical, electrical, and control designs are hardened for less-developed sites and variable grids, sustaining efficient, stable throughput across a wide range of operating conditions.

Yuantuo Advantages & Commitment

- Decades of Experience:Over 20 years in seamless-pipe heat-treatment solutions, deployed across leading pipe mills worldwide.

- Custom Engineering:Tailored line design to your grades, size range, takt time, and plant layout—ensuring the equipment aligns with your exact process route.

- Global References:Extensive applications in Russia and other international markets, recognized for dependable performance in demanding environments.

- Comprehensive After-Sales:End-to-end support from design and manufacturing through installation, commissioning, training, and long-term technical service and spare parts.

Choose Yuantuo’s induction solution for efficient, stable quench-and-temper processing of large-diameter seamless pipes.

Contact us for detailed quotations and customized engineering support.