Description

Yuantuo’s induction quenching system is engineered specifically for heat treatment of steel pipes. By leveraging high-efficiency induction heating with precise closed-loop temperature control, the line delivers accurate austenitizing and quenching for carbon steels, alloy steels, and related grades.

System Highlights

High-Efficiency Heating

Induction brings each pipe to temperature rapidly and uniformly. Compared with conventional furnaces, induction shortens heat-up time and improves circumferential/through-wall temperature uniformity—reducing risks of local overheating or underheating.

Precise Temperature Control & Automation

A Siemens-class PLC working with infrared pyrometers governs setpoints in real time. Each pipe’s heating profile is auto-adjusted to meet the specified standard, minimizing temperature spread and stabilizing metallurgical results.

Energy-Conscious, Grid-Friendly

Modular power supplies offer high efficiency and a power factor ≥ 0.95, reducing energy use and harmonic load on the plant power network—aligned with modern energy and environmental requirements.

Smart Operation, High Automation

PLC/HMI control supervises and adjusts heating, quenching, cooling, and handling parameters automatically. Operators use a touchscreen to review live data, run recipes, and make remote adjustments—simplifying operation and maintenance.

Modular Inductor & Furnace Design

Quick-change, modular inductors and heating modules are configured to pipe size and grade, increasing line flexibility and shortening changeover/maintenance time.

Application Scope

- Automotive: Heat treatment of tubular components to increase hardness and wear resistance.

- Machinery: Strength enhancement and compressive performance for mechanical parts.

- Steel Processing: General quenching of steel pipes to upgrade mechanical properties.

Heating & Treatment Process

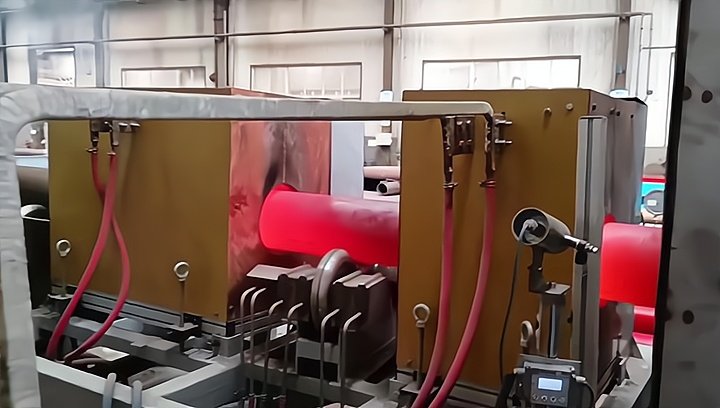

Induction Heating

Pipes are heated in the inductor to the target austenitizing temperature. Power and frequency are automatically tuned to the pipe’s size and material to ensure uniform through-thickness heating and to avoid surface over-burn or incomplete heating.

Quenching

Heated pipes enter a spray-quench chamber for rapid cooling, forming a hardened layer and significantly improving hardness and strength.

Tempering

Post-quench tempering relieves internal stresses and restores toughness, improving anti-crack performance and in-service durability.

Temperature Monitoring & Auto-Adjustment

Accurate Temperature Control

Each inductor section includes IR pyrometry for real-time measurement. The PLC adjusts power dynamically so every pipe follows the required thermal curve and meets tight process tolerances.

Automatic Adjustment

Based on pipe OD, wall thickness, and steel grade, the system auto-adjusts heating power to maintain uniformity and minimize temperature differentials.

Automated Discharge & Cooling

Automatic Discharge

After quenching, pipes are transferred via an automated outfeed to the cooling unit. Controlled handling maintains uniform cooling and prevents hot spots.

Cooling System

A high-efficiency cooling circuit—typically a closed-circuit cooling tower plus dedicated water tank—stabilizes quench/cooling performance while reducing water consumption.

Yuantuo’s induction quenching system integrates efficient induction heating with robust temperature control to provide a precise, repeatable heat-treatment solution for steel pipes. Contact us for a customized process proposal and detailed quotation.