Description

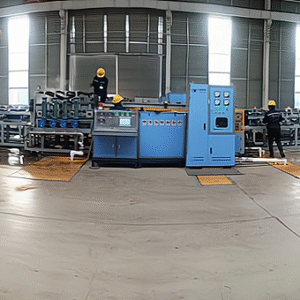

Yuantuo’s quenching line for rectangular steel uses advanced induction technology purpose-built for quenching of rectangular sections. Integrating heating, quenching, and cooling, the line delivers an efficient, precise, and energy-conscious solution for a broad range of steel grades.

Key Features

High-Efficiency Heating

High-performance induction rapidly and uniformly brings rectangular sections to temperature, ensuring even heat distribution that meets quenching process requirements while reducing energy consumption.

Precise Temperature Control & Automation

A PLC control system paired with infrared temperature monitoring precisely governs each bar’s heating temperature and dynamically trims power in real time. Every step of the Q&T cycle runs under optimal process conditions, minimizing operator variability.

Modular Inductor Design

All inductors are modular for quick changeover and easy maintenance. Coils can be configured to different section sizes and process needs, increasing line flexibility and equipment adaptability.

Fully Automated Operation

From loading → heating → quenching → cooling, the entire process is automated—reducing manual intervention, improving throughput, and enhancing operational accuracy and safety.

Energy-Conscious & Environmentally Friendly

High-efficiency power supplies and optimized inductor design cut energy usage. Induction eliminates smoke and gaseous emissions associated with flame heating, aligning with modern environmental standards.

Application Scope

Quenching, tempering, and annealing of carbon and alloy steels.

Heat processing of rectangular sections, steel tubes, and bars to improve hardness, strength, and toughness.

Deep processing for automotive, machinery, and related industries.

Heating & Treatment Process

Heating

Inductors raise the steel to the specified setpoint with uniform temperature distribution. Power and frequency are automatically adjusted to section size and grade to optimize heating quality.

Quenching

Heated material enters the spray-quench zone for rapid cooling, forming a hardened case and increasing strength.

Tempering

After quenching, parts are tempered to relieve internal stress and restore toughness, achieving the required balance of mechanical properties.

Temperature Monitoring & Auto-Adjustment

Accurate Temperature Control

Integrated IR pyrometry and PLC control provide real-time monitoring across heating, quenching, and tempering sections, maintaining tight temperature tolerances and meeting process specifications.

Automatic Power Regulation

The system adjusts heating power according to production needs and section geometry, stabilizing temperatures and optimizing each stage of the cycle.

Automated Discharge & Cooling

Automated Outfeed

After heat treatment, parts are automatically transferred through the cooling and discharge sections to the designated station—improving efficiency and reducing manual handling.

Controlled Cooling System

An automated cooling system ensures rapid, uniform cooling to preserve desired physical properties and prepare parts for downstream processing.

By optimizing the heating curve and temperature control, Yuantuo’s Rectangular-Steel Quenching Line reduces energy consumption, increases productivity, and provides a stable, reliable solution for steel heat-treatment operations.