Description

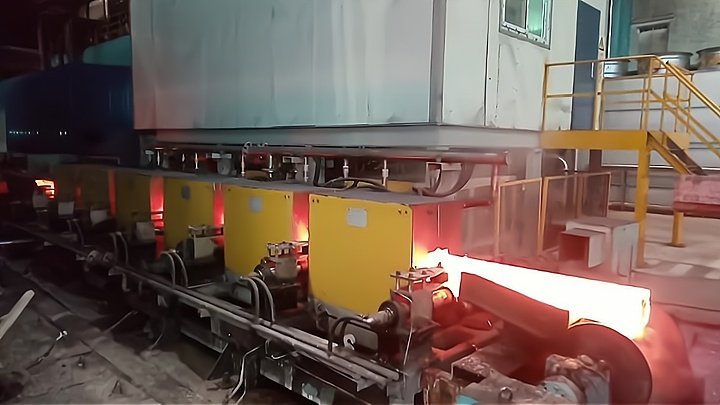

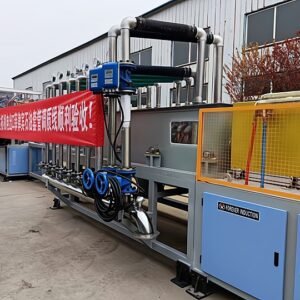

Hebei Yuantuo Electromechanical designs and manufactures a customized induction temperature-equalizing system for continuous-casting/continuous-rolling (CCM–rolling) billet lines. Purpose-built for billet re-heating/top-up heating, it raises heating efficiency and temperature accuracy at the equalizing stage, stabilizing downstream rolling quality.

Power System

- Power range: 1,000–12,000 kW

- Frequency: 500–1,200 Hz

- Flexible topology: Single power module or multi-module paralleling to match different production scales.

Throughput

Hourly output: 40–300 t/h, supporting high-capacity billet production.

Applicable Billet Sizes

- Section: 100–200 mm square

- Length: 3,000–12,000 mm

Line Advantages

Independently Driven Feeding System

Each roller axis is driven by its own motor–gear reducer. A multi-axis drive architecture under a single VFD keeps axes synchronized, improving feeding stability, pitch control, and residence-time accuracy.

Guiding System

Non-magnetic 304 stainless-steel guide wheels provide compliant axial elasticity to accommodate minor billet curvature, ensuring smooth passage through the heating section and avoiding uneven heating.

Closed-Loop Temperature Control

IR pyrometers integrated with a PLC form a closed-loop controller. Based on incoming billet temperature and line speed, power is adjusted in real time to hold a constant setpoint across the heating zone and limit temperature fluctuation.

Industrial PC (IPC) Smart Control

The IPC displays live parameters and system status with recipe memory, data logging/printing, and fault alarms. During production, power is automatically trimmed to maintain set temperature, stabilizing the process.

Yuantuo Technical Advantages

High-Efficiency Induction Heating

Advanced power electronics and coil engineering deliver rapid, uniform heating in short cycle times—reducing specific energy usage and boosting line efficiency.

Precise Temperature Control

Closed-loop control keeps each billet within the target thermal window, improving billet quality and meeting downstream rolling requirements.

Configurable Architecture

Single or paralleled power modules and coil sections are configured to billet size range and takt time, aligning the system with each plant’s capacity plan.

Stable, Reliable Operation

Engineered for varying site conditions—including grids with voltage fluctuation—the system maintains steady operation to minimize process interruptions.

Choose Yuantuo’s CCM–rolling billet temperature-equalizing induction system for efficient, precise top-up heating.

Contact us for technical details and a customized quotation.