Description

Yuantuo specializes in Q&T equipment for steel pipe, OCTG (casing/tubing), drill collars, single props, and hydraulic props. Our induction heat-treatment line combines advanced power electronics, precise temperature control, and a robust mechanical layout to boost throughput and stabilize product quality.

Primary Applications

Quench-and-temper processing of steel pipes, OCTG, drill collars, single/hydraulic props—delivering strength, toughness, and wear resistance for high-pressure, high-temperature service.

Power Architecture

- Full-body Quench: 500 kW @ 1,000 Hz

- Butt/End Upset Re-heat for Quench: 120 kW @ 1,000 Hz

- Full-body Temper: 200 kW @ 500 Hz

- Butt/End Upset Re-heat for Temper: 80 kW @ 500 Hz

This four-module layout enables precise, section-specific heating and closed-loop control across the entire Q&T route.

Size Coverage

Applicable to multiple specifications of pipes, casing, drill collars, and props. Typical OD ranges include:

Inch series (OD, in):

- 4.83–8.53

- 5.51–9.96

- 6.45–9.52

Metric series (OD, mm):

- 101.6–114.3

- 127–139.7

- 168.68–177.80

- 193.68–219.08

(Other sizes available on request.)

Line Advantages

Helical Roller Conveyance

Roller axes are set at a defined angle to the workpiece axis so each tube rotates while advancing at constant speed—improving circumferential temperature uniformity and heating efficiency. Between-inductor rollers are 304 non-magnetic stainless steel with water cooling for long, stable operation.

Individually Driven, VFD-Controlled Axes

Each feed axis has its own motor–gear reducer and VFD, allowing section-by-section speed profiles and residence-time tuning to match different grades, diameters, and wall thicknesses.

Dedicated End-Upset Re-heat (Butt Heating)

An inline re-heat station measures end-upset (butt) temperature and applies targeted induction re-heating to keep the end and body within ±10 °C, eliminating typical temperature differentials at thickened ends.

Recipe Management

The recipe system recalls process parameters automatically from inputs (grade, OD, wall thickness), reducing manual error and shortening changeovers.

Multi-Loop Closed-Loop Control

For unstable power grids, the line employs high-grade temperature/voltage feedback. It maintains process consistency even with ±20% mains-voltage fluctuation, safeguarding quality and uptime.

Why Choose Yuantuo

Proven Technology, Innovative Design

Over 20 years of induction Q&T expertise. We continuously refine coils, power stages, and control logic for efficiency, stability, and repeatability.

Custom Engineering

Turnkey, to-spec lines tailored to your process route, layout, and mechanical-property targets—helping raise productivity while lowering specific energy use.

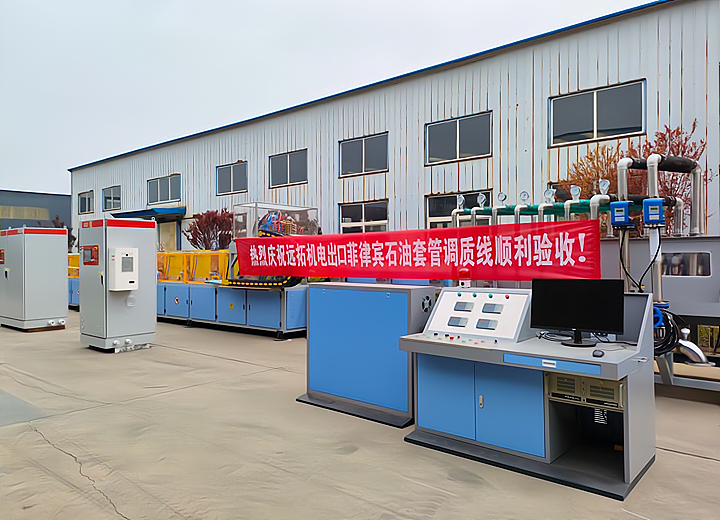

Global Deployments & Support

Extensive references in Russia and other international markets. Full lifecycle service—from installation and commissioning to operator training, long-term technical support, and spare-parts supply.

Choose Yuantuo’s Induction Quench & Temper Line for steel pipes and OCTG to upgrade throughput and product quality.

Contact us for a customized process proposal and detailed quotation.