Description

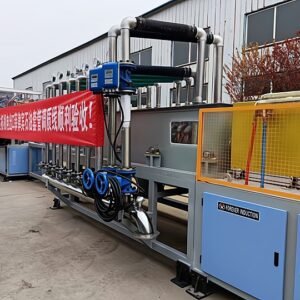

Yuantuo’s induction heating system is purpose-built for steel ball production lines. Using advanced induction technology, it heats bar stock (or ball blanks) quickly and uniformly to the target rolling temperature for carbon and alloy steels, ensuring each ball reaches the forming stand at the correct temperature—boosting throughput and finished quality.

Key Features

High-Efficiency Heating

Rapid, uniform induction heating brings stock to the setpoint with tight temperature distribution. Precise control prevents local overheat or underheat and supports consistent metallurgical properties.

Energy-Saving, Grid-Friendly

High-efficiency power modules and a modular furnace layout raise thermal efficiency and reduce energy use. The system operates at high power factor (≥ 0.90) with low harmonics to ease grid loading.

Accurate Temperature Control & Automation

A fully automatic PLC system works with infrared pyrometers to monitor bar/blank temperature in real time. Power is automatically trimmed from live temperature data so material reaches the rolling mill within ±10 °C of the target.

Smart Control, Simple Operation

Operators manage the entire process via touchscreen HMI—viewing live temperature/power, adjusting recipes, and receiving fault alarms. The system records production data and heating curves and can output reports, with USB support for data export and history recall.

Modular Furnace Design

Quick-change, modular inductors and heating sections adapt to different ball sizes and throughput requirements, shortening changeovers and maintenance and improving line flexibility.

Application Scope

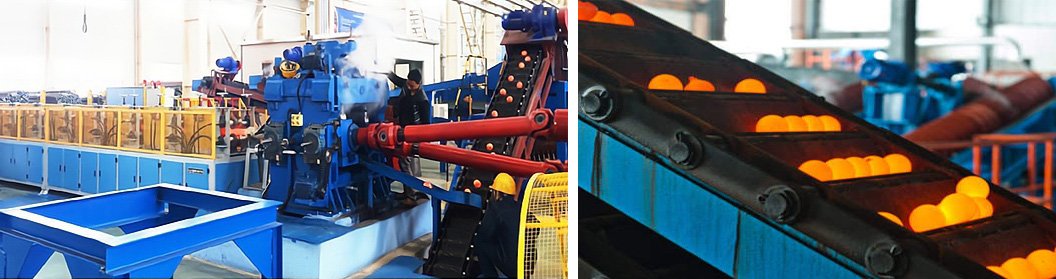

- Steel ball production: Heating of various bar sizes and grades for forming high-strength, high-hardness balls.

- Mining & metallurgy: Especially suited to wear-resistant grinding balls for mineral processing and milling.

Heating & Processing Route

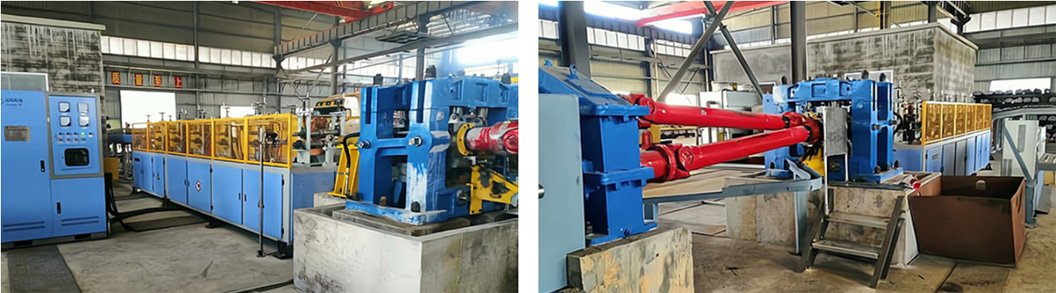

Induction Heating

Bars (or pre-cut blanks) are brought to the specified rolling temperature in an induction furnace. Power and frequency are automatically tuned to grade and section to ensure through-section uniformity and avoid surface over-burn or underheating.

Temperature Monitoring & Control

IR pyrometers track surface temperature continuously; the PLC adjusts power to keep the thermal profile stable and within tolerance across the charge.

Automated Handling & Cooling

Heated stock transfers automatically to the rolling/skew-rolling station. After forming, balls enter an automated discharge to the cooling area. A controlled cooling system (cooling tower + tank) regulates water flow/temperature/pressure to ensure uniform cooling and consistent quality while minimizing water and energy consumption.

By combining efficient induction heating with closed-loop temperature control and modular engineering, Yuantuo’s Steel Ball Heating System delivers an efficient, energy-saving, and precise solution for bar-to-ball rolling lines. Contact us for a customized process proposal and detailed quotation.