Wind-power bolts are high-strength fasteners used for long-term joints in tower and foundation assemblies. Mechanical properties depend on consistent quenching and tempering and on tight control of the surface layer—especially thread decarburization. Induction heat treatment delivers a stable thermal profile, repeatable results, and industrial throughput with a compact thermal footprint.

What the line does

Yuantuo’s line is engineered for class 8.8 and 10.9 high-strength bolts (with 8.8 as the most common). The process targets the required tensile strength, toughness, and fatigue performance while safeguarding thread integrity and limiting decarburization.

Typical process route

Loading → Cleaning → Induction heating for quench → Quenching (spray/bath) → Tempering → (Optional) in-line blackening/colouring → Unloading.Loading → Cleaning → Induction heating for quench → Quenching (spray/bath) → Interstage cleaning → Tempering → (Optional) in-line blackening/colouring → Unloading.

The entire route runs under PLC/HMI with synchronized stations.

Control & quality

PLC + HMI with IR pyrometers before/after critical zones; closed-loop temperature control

Recipe storage, event logs, batch parameter traceability

Optional in-line inspections (dimensions, hardness sampling plan)

Decarburization checks on threaded sections as specified

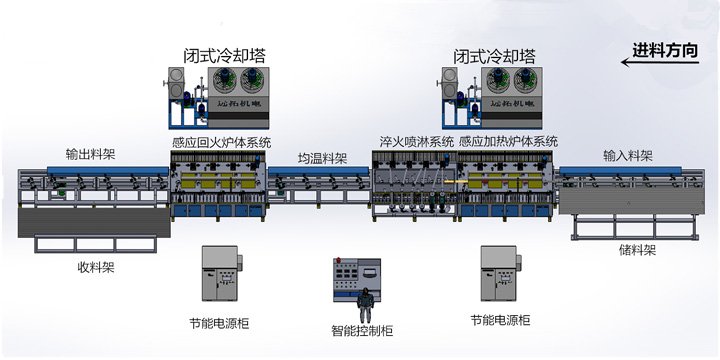

Typical setup (modular, project-specific)

Induction quench module (heating + stabilization zones)

Induction tempering module

Quench system (spray/contour or bath with medium temperature/composition control)

Transport & automatic loading/unloading (robot/manipulator optional)

Closed-loop water-cooling unit (treatment, heat exchange, pressure/flow monitoring)

Integrated control system (PLC + HMI)

IR pyrometers at critical points (dual-loop optional)

Example baseline for 42CrMo (to be validated on samples)

Heating for quench around ≈860 °C with soak (e.g., ~1.5 h at target carbon potential)

Quenching in water/water-soluble medium (typ. 6–12 % concentration)

Tempering around ≈530 °C with soak (e.g., ~2 h)

Cooling as specified in the process sheet

Final values depend on size range, chemistry, target property class, and fatigue requirements; confirmed by thermal trials. Thread decarburization must be verified.

Key advantages

Straightness of long parts: optimized handling prevents bending during heating/quenching

Full integration: auto load/unload, optional in-line blackening and checks

Precise temperature control: IR + closed loop with automatic power trim

Wide size coverage: adjustable bolt diameters and lengths, fast changeover tooling

Safety & reliability: protections for current/voltage/phases/cooling; interlocks; digital power modules

© 2018 Hebei Yuantuo Machinery Equipment Co., Ltd. All rights reserved