Quench-and-temper (Q&T) treatment for steel bars is commonly executed on an induction heating production line designed for continuous, consistent throughput. A complete line integrates power and coils, precision conveying, spray quenching, recirculating cooling, tempering, temperature feedback, PLC control, and inline quality checks. This overview helps technical buyers understand the modules and how to size them.

Loading → Pre-straightening → Induction Heating (austenitizing) → Spray Quench → Rinse → Induction Temper → Air/Water Cool → Straightness/Hardness Checks → Sorting/Packaging

Key control points: austenitizing temperature & effective soak, quench flow/pressure profile per diameter, tempering stabilization.

Note: Final values are engineered after confirming sizes, grades, hardness/case depth, distortion limits, and takt time.

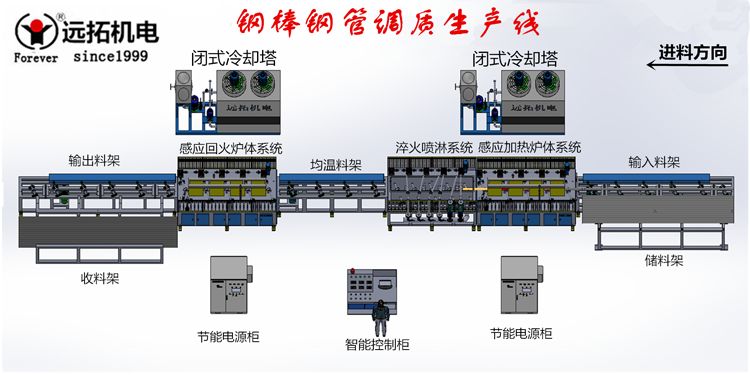

Yuantuo’s induction Q&T line, under PLC supervision, delivers controllable heating, engineered quenching, and precise tempering to achieve stable performance and reliable throughput.

© 2018 Hebei Yuantuo Machinery Equipment Co., Ltd. All rights reserved