How can we improve the hardness, wear resistance and service life of steel pipes?

A key step is quenching. Traditional quenching methods, such as gas-fired furnaces, often suffer from non-uniform heating, severe oxidation and decarburization, low efficiency and difficult process control. For modern steel and mechanical plants, induction heating has gradually become the mainstream solution for steel pipe quenching.

So, what equipment is actually used for steel pipe quenching?

In modern production, the answer is clear: steel pipe induction quenching equipment.

How a steel pipe induction quenching line works

A steel pipe induction quenching line is a highly automated system, not just a single heater. A typical line consists of:

Induction power supply – converts mains-frequency electricity into medium- or high-frequency current, generating an alternating magnetic field.

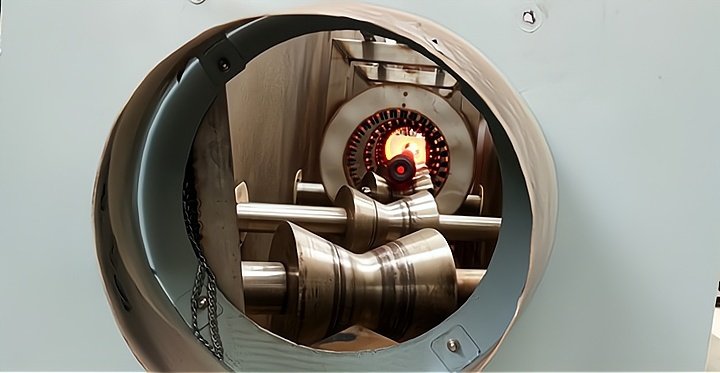

Inductor (quenching coil) – a copper-tube coil designed according to pipe diameter. When the pipe passes through the coil, strong eddy currents are induced in the pipe wall, heating it quickly to the austenitizing temperature (usually 850–950°C).

Quenching and cooling system – immediately after heating, the pipe enters a spray or immersion quenching section (water, polymer solution or oil) to achieve rapid cooling and martensitic transformation.

The basic process route is:

Loading → Rapid induction heating → Spray/immersion quenching → Unloading

This setup can be integrated with material handling, straightening, tempering and on-line testing to form a continuous, fully automatic production line.

Key advantages of induction quenching for steel pipes

Compared with traditional furnaces, induction quenching offers several decisive advantages:

High energy efficiency

Heat is generated directly in the steel pipe. Energy utilization can exceed 60%, significantly reducing power consumption per ton.

2. Accurate local heating with low distortion

The system can perform full-length or local quenching (pipe ends, weld zones, critical sections) without overheating other areas, which helps minimize deformation.

3. Uniform hardness and case depth

PLC-based control with infrared pyrometers ensures each pipe follows the same heating and cooling curve. Hardness and case depth remain consistent from batch to batch.

4. Improved surface quality

Rapid heating shortens the time at high temperature and reduces oxidation and decarburization, helping to maintain a smooth, clean pipe surface.

5. Easy automation and integration

Induction quenching lines are easy to integrate into continuous production lines, improving throughput and reducing labor intensity.

6. Safe and environmentally friendly

No open flame and no large high-temperature furnace shell. The working environment is cleaner and safer for operators.

Why choose Hebei Yuantuo for steel pipe quenching systems

As a specialized manufacturer of induction heating systems, Hebei Yuantuo Electromechanical Equipment Manufacturing Co., Ltd. designs each steel pipe quenching line according to the customer’s actual requirements:

Pipe material and diameter range

Required hardness, case depth and mechanical properties

Production capacity and layout constraints

Integration with tempering, straightening and inspection

Yuantuo’s engineering team provides complete services from process design and equipment manufacturing to on-site installation, commissioning and training, helping customers achieve a stable process and a reliable return on investment.

© 2018 Hebei Yuantuo Machinery Equipment Co., Ltd. All rights reserved