Induction Hardening & Tempering Line for Cutting Edges: A Reliable Solution for Construction Machinery Wear Parts

In the construction machinery industry, cutting edges and end bits face continuous impact and abrasion. Many manufacturers still struggle with uneven hardness, large deformation during quenching, and unstable toughness.

Hardness variation across the plate

Soft corners & overheated centers

Large distortion after flame hardening

Risk of cracking due to low toughness

High operator dependency

Inefficient energy consumption

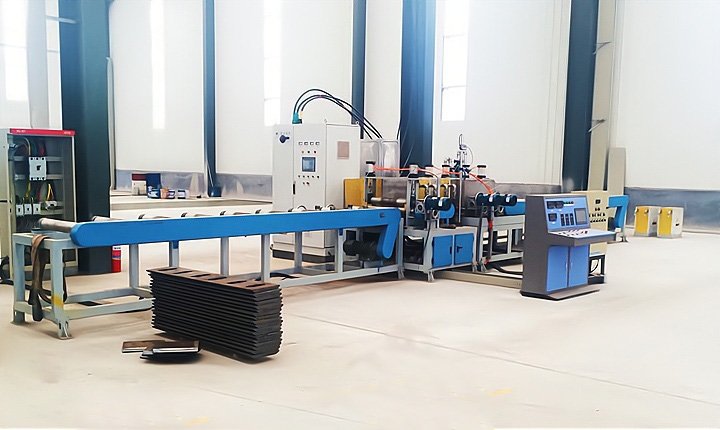

The induction hardening & tempering line provides:

Fast, uniform heating (300–1000 kW MF)

IR temperature measurement + PLC closed-loop control

Multi-zone spray quenching (enhanced corner cooling)

Continuous tempering for stable microstructure

MF induction power supply

Modular plate inductors

304 stainless-steel water-cooled rollers

IR + PLC control

Multi-zone quenching

Tempering furnace

Automatic loading/unloading

A large East China wear plate manufacturer improved wear life by 1.5–2.2 times using induction hardening & tempering.

Stable heat treatment is essential for the durability of cutting edges and wear plates.

Yuanto provides customized induction hardening & tempering solutions for construction machinery manufacturers.

© 2018 Hebei Yuantuo Machinery Equipment Co., Ltd. All rights reserved