Description

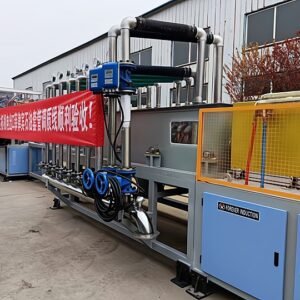

Yuantuo’s billet heating and rebar rolling line is purpose-built for billet austenitizing and subsequent rebar forming. Using advanced induction technology, it provides efficient, uniform heating for carbon and low-alloy steels, with precise temperature control to meet diverse rebar production requirements. The system delivers an efficient, energy-conscious, and reliable solution that helps improve both productivity and finished rebar quality.

System Highlights

High-Efficiency Heating & Precise Control

Induction heating rapidly brings billets to the target temperature while keeping surface-to-core ΔT within a controlled range. Specific energy per ton is managed within a practical envelope to support high-throughput rebar lines. A PLC-based automation system monitors the heating curve in real time to keep both temperature and soak time on spec.

Energy-Conscious & Grid-Friendly

High-efficiency induction power supplies operate at high power factor (≥ 0.90) with low harmonics, reducing electrical consumption and grid distortion. Intelligent temperature control adapts power to billet grade and section size to improve energy utilization.

Automation & Traceability

A Siemens PLC system provides real-time display and logging of key parameters (temperature, heating time, throughput, etc.), supporting full process traceability. Fault alarms and intuitive HMI simplify operation and help maintain stable uptime.

Modular Inductor Design & Quick Changeover

Inductors are modular with integrated lifting interfaces for fast section changes and maintenance. High-strength aluminum alloys and non-magnetic stainless steel help extend service life and reduce stray-field losses.

Productivity & Quality

Uniform, well-controlled heating minimizes temperature gradients and surface oxidation. Heated billets feed directly to the rolling mill for forming, supporting fast cycles and consistent mechanical properties in the finished rebar.

Application Scope

- Carbon & low-alloy steels: e.g., Q235, 20MnSi and similar grades

- Rebar production lines: Typical sizes include Ø12 mm, Ø14 mm, Ø16 mm and others for construction and bridge projects

Heating & Rolling Process

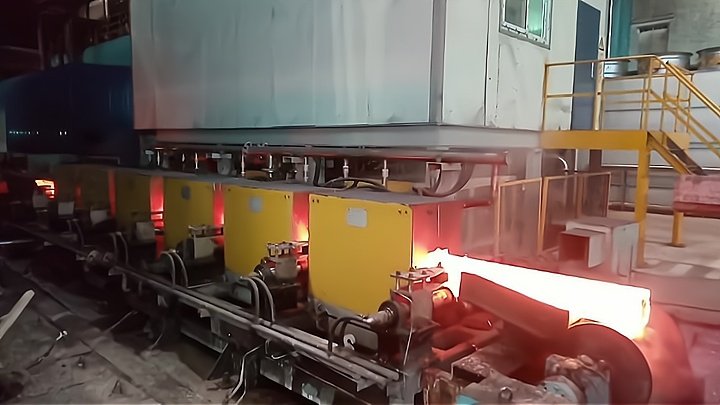

Billet Heating

Medium-frequency induction furnaces heat billets to the rolling setpoint. Power is adjusted by grade and section size to ensure through-section uniformity and limit oxidation. Tight temperature control ensures billets exit the furnace at the correct rolling temperature.

Temperature Monitoring & Regulation

Each inductor section is equipped with IR pyrometry and temperature sensors for real-time surface measurement. The PLC automatically trims power to hold the setpoint within the desired range.

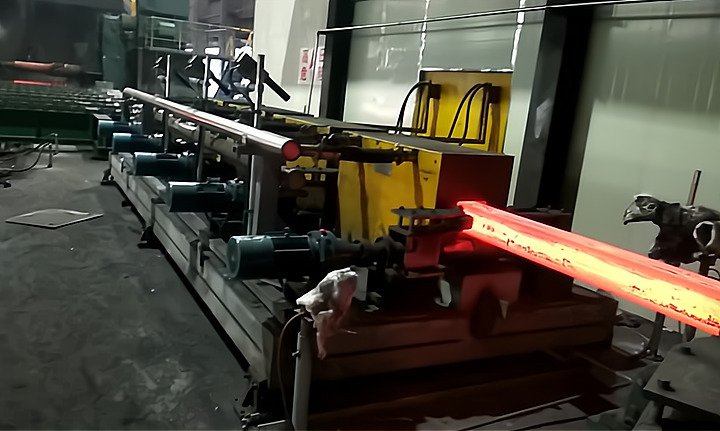

Rolling

Heated billets are conveyed to the rolling mill for deformation into rebar. Line logic adjusts rolling speed and force as required to meet dimensional accuracy and mechanical targets.

Automated Discharge & Cooling

After rolling, bars enter the cooling zone. Water flow, temperature, and pressure are controlled to achieve uniform cooling, helping to limit residual stress and surface defects while maintaining straightness.

By integrating advanced induction heating with end-to-end automation, Yuantuo’s Billet Heating & Rebar Rolling Line provides an efficient, energy-conscious, and stable solution for rebar production—supporting consistent quality for construction, bridgework, and other applications. Contact us for a customized process proposal and detailed quotation.