Description

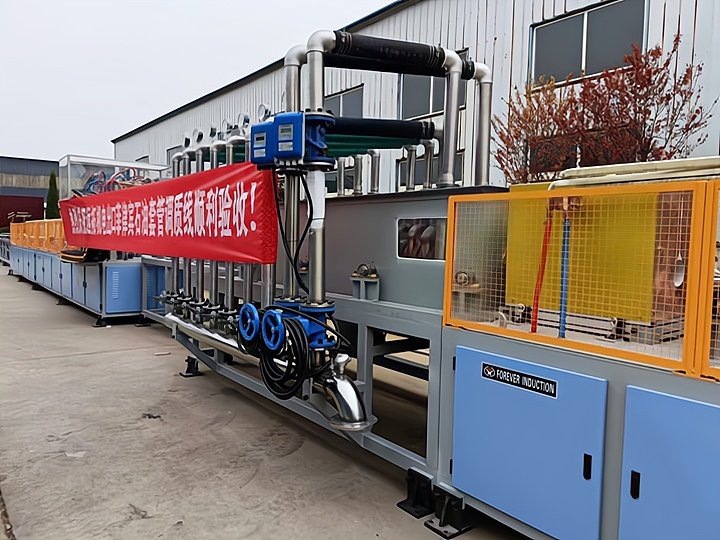

Yuantuo’s steel-pipe heat-treatment system leverages advanced induction heating for quenching, tempering, and related processes. Designed for carbon steel, alloy steel, and stainless steel pipes, it upgrades mechanical properties and wear resistance to meet modern high-strength, high-quality production requirements.

System Features

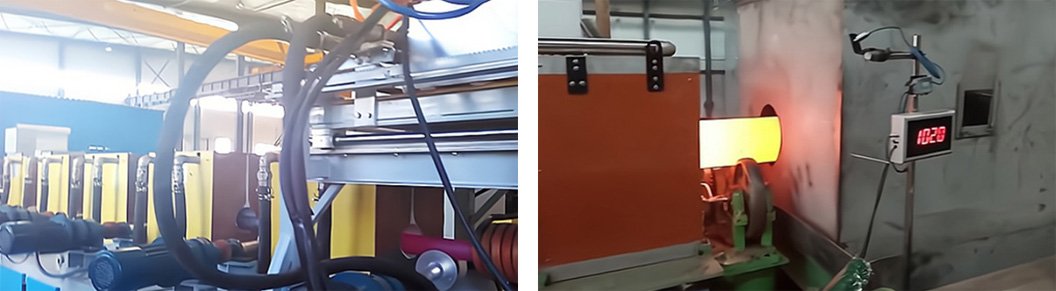

Precise Induction Heating

Using electromagnetic induction to generate surface eddy currents, the system heats pipes rapidly and uniformly. Induction provides fast heat-up, high energy efficiency, and excellent uniformity—well suited to processes requiring tight control of temperature and case/through-heating depth.

Broad Adaptability

Handles a wide range of pipe sizes and materials. From OCTG to general industrial tubing, the line supports quenching, tempering, and full quench-and-temper workflows with stable, repeatable results.

Full Automation

A PLC-based control system automates loading, heating, quenching, tempering, and cooling. Automation improves throughput, reduces operator variability, and maintains process accuracy and consistency.

Modular Inductor Design

Quick-change inductors simplify installation, removal, and maintenance, reducing downtime and maintenance costs. Modular configuration allows flexible setups tailored to different production needs.

High-Efficiency Cooling

Post-quench cooling is engineered for rapid, uniform temperature reduction to achieve target hardness and wear performance. The cooling layout promotes even cooling to minimize residual stress and surface defects.

Application Scope

- Carbon steels: Typical for OCTG, construction, and pipeline applications

- Alloy steels: For higher strength or corrosion-resistant requirements in energy, oil & gas, and chemical sectors

- Stainless steels: For tubing requiring enhanced wear, oxidation, and corrosion resistance

The system meets diverse needs for quenching, tempering, and full quench-and-temper processing, providing a stable, dependable solution across industries.

Heating & Process Flow

Quenching

After precise induction heating to the austenitizing temperature, pipes are rapidly cooled to raise surface hardness and wear resistance. Induction’s uniformity helps avoid overheating and surface defects.

Tempering

Tempering follows quenching to relieve internal stresses and restore toughness, improving anti-crack performance and overall mechanical balance.

Auto-Follow Heating

For varying diameters and wall thicknesses, the control system automatically adapts power/frequency and line speed to keep the heated zone uniform and within spec.

Controlled Cooling

A dedicated cooling section ensures fast, uniform cooling while maintaining surface quality and straightness, helping prevent distortion or cracking due to excessive temperature gradients.

By combining advanced induction technology with end-to-end automation, Yuantuo’s Steel-Pipe Heat-Treatment Equipment delivers an efficient, precise, and flexible solution for upgrading pipe performance. Contact us for customized process recommendations and a detailed quotation.