Description

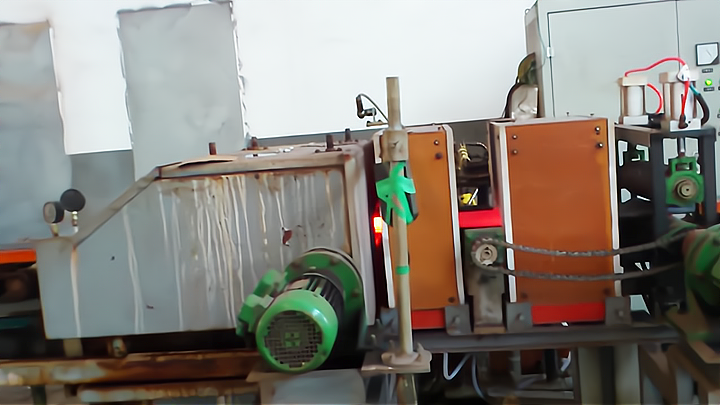

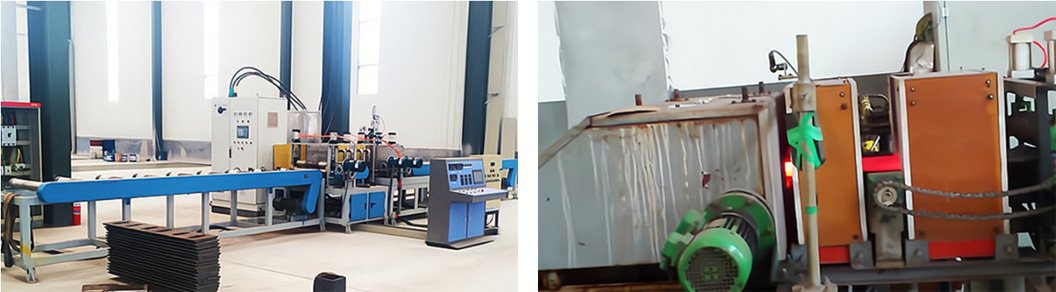

Yuantuo’s heat-treatment line is purpose-built for quenching and tempering construction-machinery cutting edges and corner (end-bit) plates. With advanced induction technology and an efficient line layout, it delivers precise, reliable, and productive heat-treatment performance.

Power System

Quenching Power: 300–1,000 kW @ 0.5–4.0 kHz

Workpiece Envelope

Flat plates (W × T, mm):

152×16, 203×16, 203×19, 152×19, 203×25, 200×19, 200×25, 300×30, 330×30, 304×40, 406×40, 406×45, 330×40, 330×35, 330×32

Curved plates (W × T, mm):

152×13, 152×16, 203×16, 203×19, 152×19, 203×25

Length range: 0.5–3.5 m

(Typical applications cover dozers, loaders, graders, and other earth-moving equipment.)

Line Advantages

Conveyor Roller Engineering

- Between inductors: non-magnetic 304 stainless-steel rollers with water cooling for stable, efficient heating.

- Other roller sections: 45# (C45) steel with surface hardening to enhance wear resistance and service life.

Grouped, Independently Controlled Roller Sections

Infeed, inductor, and outfeed roller groups are controlled independently. This stabilizes continuous heating, minimizes gaps between parts, improves temperature uniformity, and increases throughput.

Automatic Temperature Control

Infrared pyrometers integrated with a PLC form a closed-loop temperature system that precisely controls quench and temper setpoints, ensuring each workpiece meets specified hardness and mechanical-property targets.

Industrial PC (IPC) Smart HMI

Real-time status display with recipe memory, data storage, print/export, fault indication, and alarm functions—simplifying production monitoring and maintenance.

Why Choose Yuantuo

Efficient Induction Heat-Treatment

Advanced coil and process design deliver rapid, uniform heating with accurate quench temperature control—improving strength and wear performance of cutting edges and end bits.

Customized to Your Process

Tailored line engineering to match your grades, geometries (flat/curved), takt time, and plant layout—maximizing productivity and fit with your downstream operations.

Robust, Flexible Design

Handles a wide range of plate sizes and shapes while maintaining stable, repeatable quench-and-temper quality.

Global Support

Proven deployments across global markets—including Russia and other regions—backed by comprehensive after-sales service to keep your line running at high efficiency over the long term.

Choose Yuantuo’s induction heat-treatment system to boost productivity and product quality.

Contact us for technical support, customized proposals, and detailed quotations.