Description

Primary Applications

Designed for quench-and-temper processing of steel bars, low-carbon alloy bars, wind-power bolts, anchor/foundation bolts, lead/ball screws, and hydraulic cylinder rods. The line delivers controlled quenching and tempering with high productivity and precise process control.

Specifications & Working Range

Power System

- Quenching: 160–3,000 kW @ 0.5–4 kHz

- Tempering: 100–2,000 kW @ 0.5–2.5 kHz

Throughput

0.5–7 t/h (depending on size, grade, and process route)

Size Envelope

- Diameter: Ø20–Ø200 mm

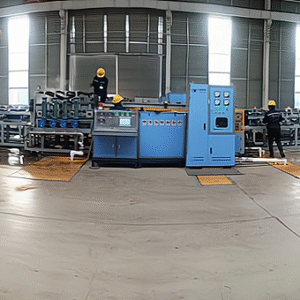

Conveyor & Mechanical Design

Helical Roller Geometry

Roller axes are set at a defined angle to the workpiece axis so each bar rotates while advancing at constant speed, improving circumferential and through-section heating uniformity.

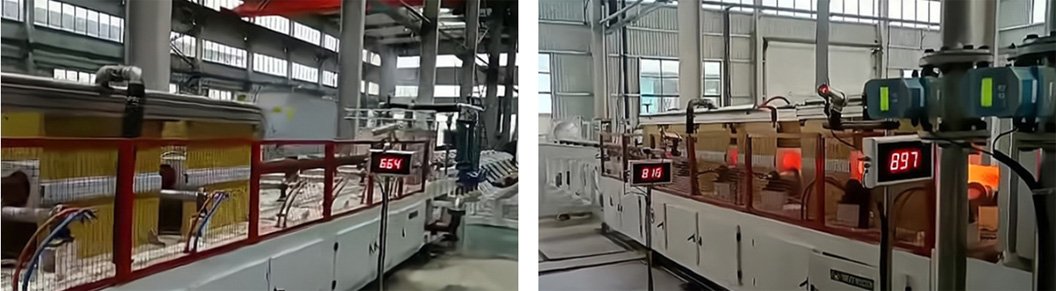

Roller Materials

- Between inductors: non-magnetic 304 stainless-steel rollers with water cooling for thermal stability and long service life.

- Other sections: 45# (C45) steel with surface hardening for wear resistance.

Grouped Roller Control

Infeed, heating (inductor), and outfeed roller groups are independently controlled. This stabilizes continuous heating, reduces inter-part gaps, and supports consistent residence time.

Control & Automation

Closed-Loop Temperature Control

Infrared pyrometers integrated with a PLC form a closed loop for both quench and temper sections, maintaining setpoints and minimizing temperature deviation.

Industrial PC (IPC) HMI

Real-time display of operating parameters with data logging, recipe storage, print/export, fault indication, and alarms, supporting safe operation and traceable quality.

System Advantages

- High Productivity: Processes 0.5–7 t/h to meet mid- to large-scale production requirements.

- Efficient Heating: Uniform, precisely controlled induction heating improves metallurgical consistency and reduces rework.

- Energy-Conscious Operation: Modern induction power supplies with high power factor help lower specific energy consumption.

- Operator-Friendly: Advanced temperature control and equipment management simplify operation, changeover, and maintenance.

Choose Yuantuo’s induction quench-and-temper line to achieve stable quality and dependable throughput for steel bars and fasteners.

Contact us for a customized proposal and detailed quotation.