Description

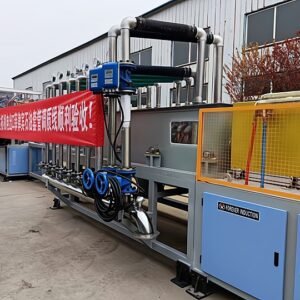

Hebei Yuantuo designs and manufactures an induction heating system engineered for hot rolling of metallic long products such as rebar and stainless steel. Using advanced induction technology, the system heats a wide range of sizes efficiently while keeping pre-rolling temperature uniform for stable rolling and high productivity.

Power & Throughput

- Power range: 1,000–5,000 kW

- Frequency range: 2.5–15 kHz

- Typical size range (rebar/rounds): Ø12–Ø32 mm

- Throughput: 2.5–15 t/h (configurable to production scale)

Supported Materials

M2 high-speed steel (HSS)

11Cr17 martensitic stainless steel

Carbon steel rebar

Line Advantages

1) High-Efficiency Induction Coil Design

Variable-pitch, graded-temperature coil engineering maximizes heating efficiency and circumferential/through-section uniformity—delivering ideal thermal conditions at the mill stand.

2) Elastic, Adjustable Rollers

Compliance-adjustable pinch/hold-down rollers ensure steady feeding for changing diameters. Inter-inductor roller tables are built from 304 non-magnetic stainless steel with water cooling for stable operation at elevated temperatures.

3) Precise Temperature Control

An infrared pyrometer at the furnace exit continuously monitors bar/rod temperature to match the required entry temperature at the rolling mill, improving pass stability and rolled quality.

Technical Advantages

High-Performance Induction Heating

The long-span induction layout with variable coil geometry achieves fast, efficient heating in short residence times—raising throughput and reducing specific energy consumption.

Flexible Mechanical Adjustment

Elastic, adjustable rollers accommodate multiple diameters and profiles, maintaining consistent feed and residence time for uniform heating.

Accurate Thermal Control

IR temperature feedback ensures uniformity across heating and rolling, preventing temperature-driven quality deviations and helping finished properties meet specification.

Stability & Reliability

Designed for continuous, high-duty service: 304 non-magnetic stainless structures and closed-loop water cooling enhance durability and long-term reliability.

Choose Yuantuo’s induction heating system for long-product rolling to increase mill efficiency and product quality.

Contact us for technical support and a customized quotation.