Description

Yuantuo’s quench-and-temper line uses advanced induction technology purpose-built for heat treatment of steel bars. Covering the full cycle—heating, quenching, and tempering—the line upgrades mechanical properties across carbon and alloy steels, delivering high hardness, high strength, and excellent toughness.

Key Features

High-Efficiency Heating

High-performance inductors heat bars rapidly and uniformly to the target temperature, ensuring even heat distribution that meets demanding Q&T requirements while reducing energy use.

Precise Temperature Control & Automation

A PLC system combined with infrared pyrometry precisely regulates each bar’s temperature and dynamically trims power in real time so every stage runs under optimal process conditions.

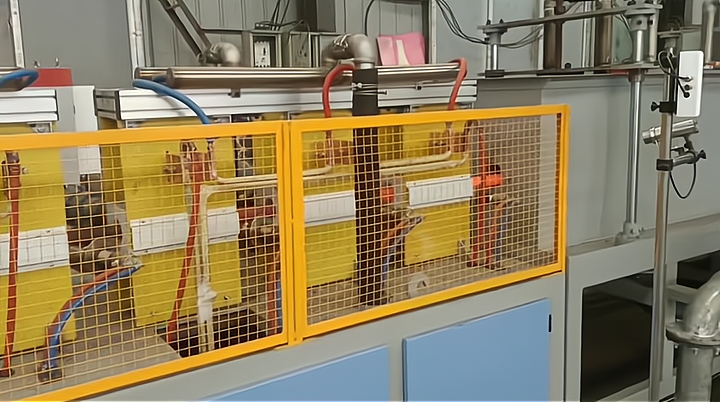

Modular Inductor Design

Quick-change, modular inductors simplify maintenance and enable flexible setups for different sizes and grades.

Fully Automated Operation

From loading → heating → quenching → tempering → discharge, the process is fully automated to minimize manual intervention, improve throughput, and enhance consistency.

Energy-Conscious & Grid-Friendly

High-efficiency power supplies and optimized coil design lower specific energy consumption and reduce harmonic load on the plant power network.

Application Scope

Carbon & alloy steels: Quenching, tempering, and related treatments for components in automotive, machinery, and tooling industries.

General metal heat treatment: Q&T (and, when needed, annealing) for bars, tubes, and other long products to increase hardness, strength, and toughness.

Heating & Process Route

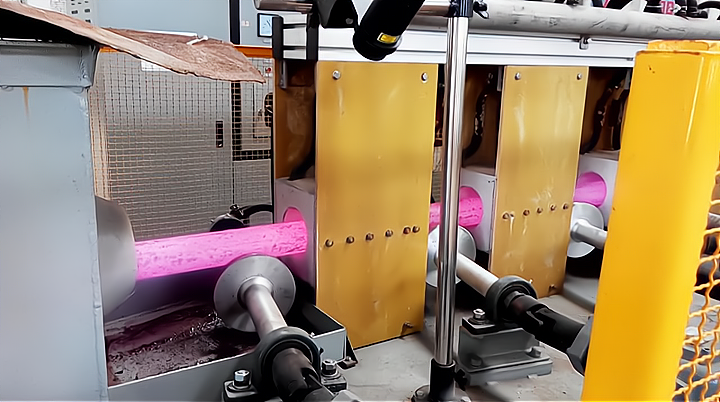

Bar Heating

Inductors raise bars to the specified temperature. Power and frequency are automatically adjusted to section size and grade to ensure uniform through-section heating.

Quenching

Heated bars pass through a spray-quench zone for rapid cooling, forming a hardened case and increasing strength and wear resistance.

Tempering

Post-quench tempering relieves internal stresses and restores toughness, achieving the required balance of mechanical properties.

Temperature Monitoring & Auto-Adjustment

Closed-loop temperature control—PLC + IR pyrometers—monitors each bar in real time and adjusts power to keep temperatures within process tolerances during heating, quenching, and tempering.

Automated Discharge & Cooling

After heat treatment, bars automatically transfer through the controlled cooling and outfeed sections to the designated station, improving efficiency and preparing parts for downstream operations.

By integrating advanced induction heating with end-to-end automation, Yuantuo’s Steel Bar Quench & Temper Line provides an efficient, energy-saving, and precise solution for bar heat treatment. Contact us for a customized process proposal and detailed quotation.