Description

Yuantuo’s surface-quenching system applies advanced induction technology to harden the surfaces of carbon and low-alloy steel bars. Widely used in machinery manufacturing, automotive components, and steel processing, it delivers an efficient and precise heat-treatment solution.

Key Features

High-Efficiency Surface Quenching

Induction heating rapidly and uniformly raises the bar surface to the target quench temperature, producing a consistent hardened layer and balanced mechanical performance.

Precise Temperature Control & Automation

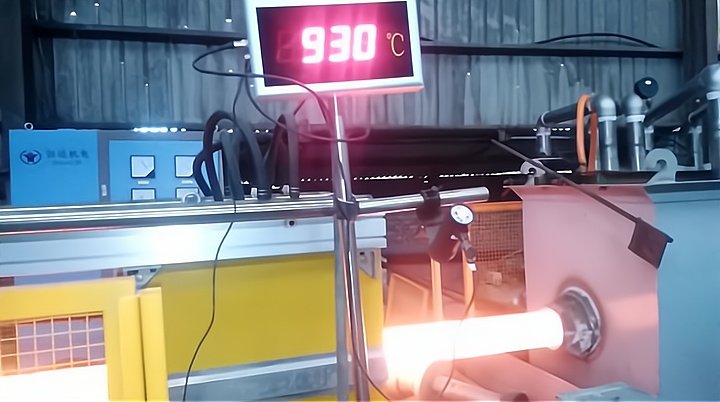

A Siemens PLC paired with infrared pyrometry provides real-time monitoring and closed-loop control. Heating power is automatically adjusted to meet the specified surface-hardening requirements for each workpiece.

Modular Inductor Design

Quick-change, modular inductors support fast maintenance and size changeovers, improving flexibility and line efficiency across different bar specifications.

Energy-Conscious & Grid-Friendly

High-efficiency induction power supplies operate at high power factor with low harmonics—reducing energy consumption and minimizing impact on the plant power network.

Application Scope

- Carbon & alloy steels: Surface hardening of bars and shaft-type parts commonly used in automotive and general machinery.

- General heat treatment: Surface hardening and strengthening of bars and (where applicable) tubes to increase wear resistance and strength.

Working Principle & Process

Loading & Heating

Bars are automatically conveyed into the inductor. Induction heating quickly elevates the surface temperature to the austenitizing setpoint.

Quenching

Immediately after heating, bars pass through a spray-quench zone. A high-hardness case forms while the core retains toughness, improving overall mechanical balance.

Temperature Monitoring & Control

IR pyrometers track each bar’s temperature in real time. The PLC regulates power to maintain the required thermal profile and case-depth target.

Discharge & Cooling

Post-quench bars proceed through a controlled cooling section, then transfer to downstream handling or packaging.

System Configuration

- Induction Power Supplies: High-efficiency modules tailored to the process route deliver stable, uniform power output.

- Inductor Coils: Custom-designed to bar size and target case depth for uniform heating and reduced thermal loss.

- Capacitor Banks & Quench Transformer: Sized for efficient reactive-power management and stable quench power delivery.

- Infrared Temperature System: Full-process monitoring to ensure precise temperature control during austenitizing and quenching.

- PLC/HMI Control: Siemens PLC with a 10-inch color touchscreen for live data display, recipe management, automatic parameter adjustment, fault indication, and alarms.

By combining advanced induction heating with end-to-end automation, Yuantuo’s Surface-Quenching System for Steel Bars supports consistent case hardness, improved toughness, and streamlined production—providing stable, reliable performance for diverse customer needs.