Description

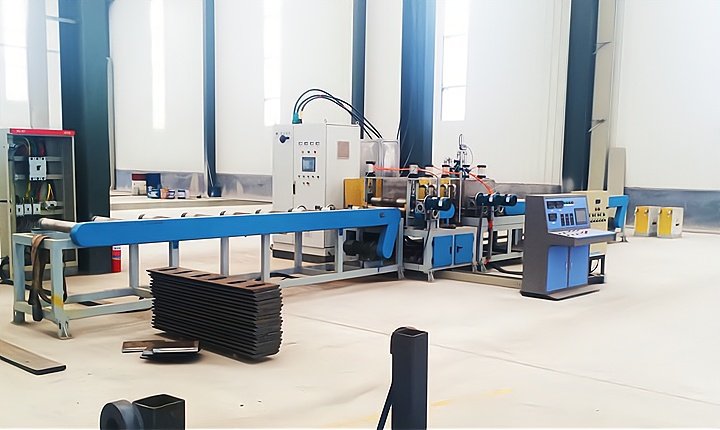

Yuantuo’s Through-Heating Quench Line employs advanced induction technology purpose-built for through-heating and quenching of steel plate and other metallic flat stock. With precise temperature control and high-efficiency heating, the line enables plates to reach target properties during quenching and tempering, and is widely used in automotive, machinery, and tooling industries.

System Highlights

High-Efficiency Induction Heating

Rapid, uniform induction heating brings plates to the required austenitizing temperature. Compared with conventional furnaces, induction offers higher thermal efficiency and can markedly reduce surface oxidation loss during heating.

Precise Temperature Control & Automation

A PLC control system coordinated with infrared pyrometers precisely manages plate temperature. Real-time data collection ensures uniform temperature distribution, delivering stable and consistent quench results.

Modular Inductor Design

Modular inductors allow fast coil changeover and maintenance. Inductors can be customized to plate size and grade, providing flexible production options.

Fully Automated Operation

From loading → heating → quenching → cooling → discharge, the entire process is fully automated—reducing manual intervention and variability while improving throughput and operational safety.

Energy-Saving & Environmentally Friendly

High-efficiency power supplies and inductor design help cut electrical consumption and lower harmonic pollution to the grid. Induction heating also avoids the smoke and gaseous emissions associated with flame furnaces.

Application Scope

Quench and temper of carbon steel, alloy steel, and related grades for automotive and construction-machinery applications.

General metal heat treatment—especially deep processing of steel plate (and, where required, steel tube)—to improve hardness, strength, and toughness.

Pre-treatment of steel materials to refine structure and properties, enhancing wear and corrosion resistance.

Heating & Treatment Process

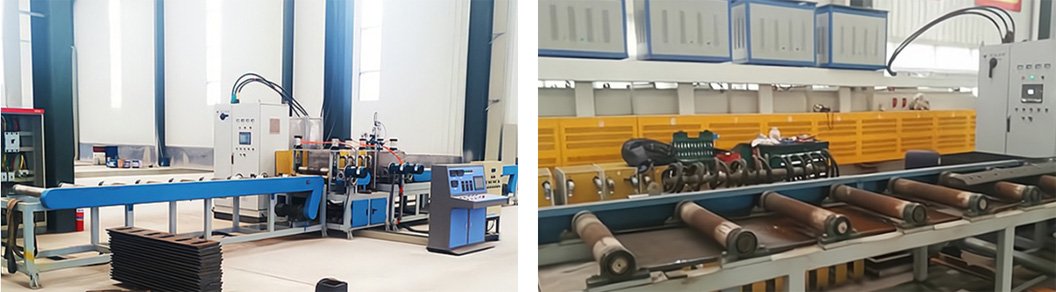

Plate Heating

Plates are heated by inductors to the specified through-heating temperature. Based on plate thickness and grade, the system automatically adjusts power and frequency to ensure uniform through-thickness heating.

Through-Heating Quench

Heated plates pass into the quench zone, where spray quenching rapidly cools the plate to transform the microstructure and increase hardness and strength.

Tempering

After quenching, plates are tempered to relieve internal stresses and restore toughness, ensuring stability and durability in service.

Temperature Control, Monitoring & Auto-Adjustment

Accurate Temperature Control

Each inductor section is equipped with temperature sensors and IR pyrometers for real-time monitoring. All temperature data are logged by the PLC for traceability and process optimization.

Intelligent Adjustment

According to plate size, thickness, and production requirements, the system automatically adjusts power and frequency to maintain optimal heating conditions.

Automated Discharge & Cooling

Automatic Discharge

After quenching, plates are transferred by an automatic discharge system to the cooling unit. Full automation improves line efficiency and ensures uniform, controlled cooling.

High-Performance Cooling

An efficient cooling system rapidly lowers plate temperature while avoiding splash, over-cooling, or other issues common in traditional cooling methods.

Yuantuo’s Through-Heating Quench Line integrates induction heating with end-to-end automation to deliver an efficient, energy-conserving, and precise quenching solution. By optimizing the heating curve and maintaining tight temperature control, the system significantly enhances plate hardness, strength, and toughness—while reducing energy usage.