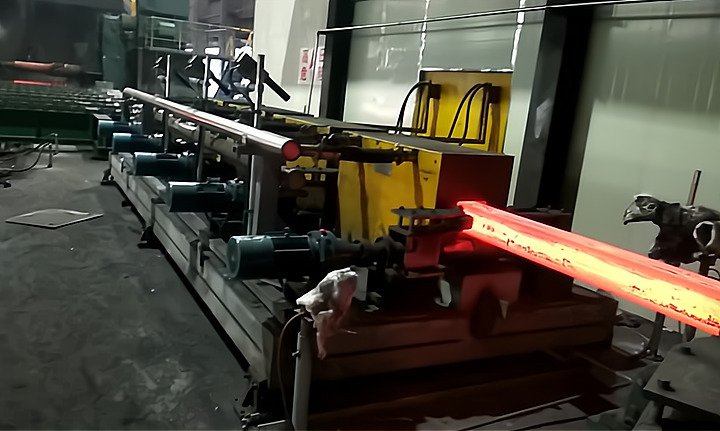

In steel mills and forging shops, billet heating is the first critical step before all downstream processes.

If this step is unstable, you quickly see problems in rolling and forging:

Dimensional deviations, bending and twisting

Surface cracks, laps and heavy scale

Higher rolling loads and accelerated equipment wear

High energy consumption and electricity cost per ton of steel

No surprise that many buyers ask first: “Which electric billet heating furnace is the best?”

From an engineering perspective, there is no single universal answer. A more practical question is: which supplier can help you balance temperature control, energy consumption, reliability and service under your specific conditions. That is usually your “best” choice.

An electric billet heating furnace heats continuous-cast, square or round billets from ambient or intermediate temperature up to the rolling/forging range, typically 1100–1250 °C. Common applications:

Equalizing and reheating continuous-cast billets before hot rolling

Overall billet heating before forging

Reheating before hot rolling

Preheating and soaking of special steel grades

Key process requirements can be summarized in four points:

Uniform temperature

Small temperature gradients between surface and core

Controlled head–tail and edge–center differences

No “hot outside–cold inside” and no local overheat/burning

Controllability and repeatability

Adjustable heating curve and soaking time for different grades and sizes

Stable discharge temperature to support standardized downstream practice

Energy performance

kWh per ton of steel kept within a reasonable range

Competitive overall cost compared with gas-fired or other traditional solutions

Stable operation and maintainability

Proven 24/7 operation capability

Accessible spare parts, after-sales service and remote diagnostics

A good furnace is not the one with the most aggressive brochure, but the one that reaches the best overall compromise between these targets in your plant.

Today, typical billet heating options include:

Gas-fired reheating furnaces – mature and familiar, but with long heating time, heavy scale formation and temperature uniformity dependent on furnace condition and operator skills.

Resistance and bogie-hearth electric furnaces – accurate temperature control and gentle heating, but limited flexibility when you need high throughput, frequent size change and high automation.

Medium-/low-frequency induction billet heating furnaces – fast heating, high efficiency, precise adjustment to billet size and charging rhythm, good uniformity and repeatability, and flexible start/stop well suited to continuous casting and rolling/forging cycles.

Induction systems do impose higher requirements on power topology, coil design, electromagnetic matching and system integration (power + furnace + handling + temperature measurement + control).

Yet in the last decade, more and more billet heating projects have chosen induction because, in terms of energy per ton, efficiency, automation and labor, induction technology often provides controlled investment with a clear long-term payback.

Instead of asking “who is the best in general”, use these six questions to see who is best for you:

Heating quality and temperature control

What discharge temperature uniformity can they demonstrate (head vs. tail, edge–center, surface vs. core)?

Do they use infrared pyrometers + PLC/IPC closed-loop control?

Under defined conditions, can discharge temperature stay within ±5–±10 °C long term?

Do they provide recipe management for different sizes and grades, with one-click recipe change instead of manual tuning only?

2.Energy efficiency (kWh/t)

What is the designed kWh/t range under your conditions?

Do they have real plant data, not only ideal figures?

Is power factor high (≥0.95)? Are losses traceable? Is multi-power-source operation optimized to avoid long low-load operation?

Can they help you calculate a realistic payback period based on your annual tonnage and current energy cost?

Integration with your production rhythm

How will the furnace match continuous casting, existing furnaces, rolling mills or presses?

Is billet storage, charging and queuing realistically planned for your layout?

Can the system automatically adjust power and speed according to target throughput?

Reliability of power supply and furnace design

Is the power topology proven in many similar projects?

Are key components properly selected with reserves?

Are coil cooling, leak prevention and short-circuit protection well engineered?

Are there functions for fault self-diagnosis, real-time monitoring and remote support?

Automation and digitalization

Can the system connect to MES/ERP?

Does it log temperature, power, speed, steel grade and size for each batch?

Are one-button start/stop, recipes and alarm history supported for traceability?

Service and industry experience

How many real references do they have in steel and forging?

Will they prepare a process evaluation and layout proposal for your plant, or only quote a furnace price?

Is there a clear plan for training, response times and spare parts?

Turn these criteria into a simple comparison checklist and go through it with each candidate.

The supplier who best fits your process, helps you reduce total cost and is willing to work with you on long-term optimization is, in practice, your “best” electric billet heating furnace supplier.

© 2018 Hebei Yuantuo Machinery Equipment Co., Ltd. All rights reserved